STATE OF THE ART COMPOSITES

Seawind is in continuous development with every new model, building on the knowledge and success of previous designs. Every boat is the result of hundreds of collective years of multihull experience, and the best construction techniques the world has to offer.

STATE OF THE ART COMPOSITES

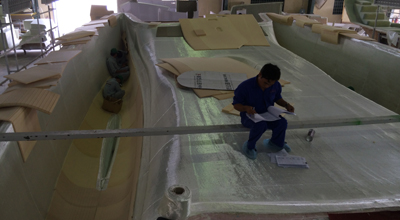

INNOVATORS OF RESIN INFUSION

Seawind uses Resin Infusion Technology to produce a lighter, stronger, and cleaner product. In partnership with High Modulus and DIAB technologies, the complex infusion implementation process was developed using a 3D simulated flow model (pictured here) to ensure that best quality and consistency is achieved with every new Seawind.

STATE OF THE ART COMPOSITES

INNOVATORS OF RESIN INFUSION

Seawind has always been a technological leader in both pioneering new features and adopting up and coming manufacturing practices. The company has used vacuum formed laminates throughout it’s entire history and moved to infusion in the construction of hulls back in 2007. Since then we have come a very long way with all components now 100% vacuum formed, in fact we are proud to say we don’t own a single chopper gun machine, a tool used industry wide for producing fast and cheap composites at the detriment of weight and strength.

STATE OF THE ART COMPOSITES

INNOVATORS OF RESIN INFUSION

Only the best materials are used in the construction of our vessels. Whether it be carbon daggerboards and masts, Kevlar hull bottoms, e-glass structures or thermoformed cores, we import only the very best! We source our materials from the world over, on a constant hunt for new and better technologies. We do this, not to build the fastest or even the lightest boats in the world, we do this to provide our customers with the best possible value.

STATE OF THE ART COMPOSITES

INNOVATORS OF RESIN INFUSION

Partnering with industry leaders in composite engineering has enabled Seawind focus on optimizing lamination processes while sharing our extensive production experience with the tried and tested engineering teams of Diab, High Modulus and ATL composites.

Striving for Excellence

Following Seawinds acquisition of Corsair Marine International in 2010, one of the first major actions was to identify the strengths of each company, ensuring that none would be lost while integrating the production of both brands. Corsairs performance pedigree had promoted ongoing innovation in their lamination and construction methods, with greater focus on the weight the finished boat than had been required for the more cruising-orientated Seawind product range.

Integrating Seawind models into the Corsair lamination process resulted in significant weight savings. It involved both changes to the materials (on a strand fiber level) and to the resin infusion technique (resulting in an improved resin to fibre ratio), finally arriving at hulls and decks for each model being 30% lighter than previously achieved.

Research Led

Seawind also invested in researching many high quality materials – including core structures. For the bulk of the Seawind components, the materials have not changed however those that have been, have achieved outstanding results. Plywood previously used in through bolted areas of our deck laminate has now been replaced with high density closed cell foam. All shelves, dividers and bulkheads previously constructed from marine plywood are now closed cell pvc foam cored, vacuum bagged, fibreglass panels, equating to greater strength, less weight and removing the looming possibility of rot. And now tables, doors and shelving are being constructed using foam coring rather than heavy, solid timber panels.

Result-Oriented

Lighter boats perform better under both motor and sail, saving fuel and getting you to your final destination sooner. However, in our hunt for kilos it has become apparent that there are many other areas benefiting from this attention to process. The lost weight has resulted in boat platforms which operate under reduced stress on the overall structure – meaning a safer, even more reassuring boat. The hardware products we now install are of a higher standard to those previously used. So our catamarans are not only faster but they are also smoother and easier to manoeuvre than we had ever thought possible.

What's New

CONTACT US

Tel +84 28 3873 3630

Sales Enquiry:

Customer Service Enquiry:

© 2026 Corsair Marine International. Alls rights reserved.